As people's demand for quality kitchen appliances and food safety continues to rise, the oven, a high-temperature cooking tool, is becoming increasingly popular in home and commercial kitchens. In the core structure of the oven, the choice of material for the liner is particularly critical, which not only directly affects the service life of the oven and baking effect, but also relates to the convenience of daily cleaning and food contact safety. Among many materials, 304 stainless steel has become the preferred material for oven liners due to its excellent performance and food-grade safety features.

304 stainless steel in the food industry

Stainless steel 304 is an austenitic stainless steel containing 18% chromium (Cr) and 8% nickel (Ni), so it is also known as “18/8 stainless steel”. It is one of the most widely used stainless steel materials today, and is used in a large number of applications not only in the food service, medical, mechanical and chemical fields, but also in the home appliance industry. In products such as refrigerators, dishwashers, electric kettles, microwave ovens and ovens, especially the surface of 304 stainless steel after brushed treatment, with its good corrosion resistance, aesthetic and wear-resistant, in the high-end kitchen appliances frequently appear. In the brushed process, 304 stainless steel surface shows a detailed and uniform metal texture, not only to enhance the overall texture of the product, but also has a certain anti-fingerprint, anti-scratch performance. Because of this, it is widely used in the production of oven shell and liner. Especially in the inner liner part, brushed 304 stainless steel can withstand a long time of high temperature baking, but also easy to clean, is the combination of practicality and aesthetics of the ideal material. From the perspective of food safety, 304 stainless steel is also recognized as a “food contact grade” material. In the daily baking, the oven liner is often in direct contact with grease, seasoning, food residues, which puts forward higher requirements for the safety of the material. 304 stainless steel has a very low risk of metal precipitation, even at high temperatures and high humidity environment, will not release hazardous substances to contaminate the food, and is therefore widely used in the field of tableware, cooking utensils, food processing equipment and so on. In addition, it also has good antibacterial properties and strong cleaning convenience, can effectively avoid bacterial growth, to protect food hygiene.

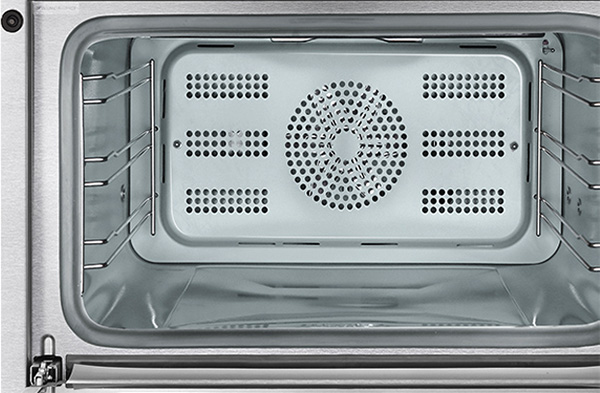

Requirements for stainless steel oven liners

As the structural component closest to the heat source when the oven is working, the inner liner not only has to face frequent high-temperature baking, but also needs to resist multiple corrosion challenges from ingredients, water vapor, fumes and cleaning agents. This requires the liner material in the following aspects of outstanding performance: first of all, high temperature performance, to be able to withstand a long time 200 ℃ or even higher temperatures without deformation, no discoloration, no release of harmful components; secondly, corrosion resistance, the face of acid and alkali, grease and other long-term erosion is still stable; thirdly, strong mechanical strength, to prevent cracks or deformation due to heat expansion and cold contraction; and finally easy to clean and maintain, reduce the cleaning burden and maintain the use of hygiene. The last is easy to clean and maintain, reduce the burden of cleaning and maintain the use of health. And 304 stainless steel is to meet the above conditions of the excellent material. The upper limit of its heat-resistant temperature up to 800 ℃ or more, fully capable of high-temperature conditions of the oven; its chromium element formed by the oxide film greatly enhanced the corrosion resistance, so that it is not easy to rust, flake; good ductility and welding performance also facilitates the liner structure of the industrialization of the processing and manufacturing; In addition, after brushed or mirror treatment of the 304 stainless steel surface is more smooth and flat, not easy to adhere to the oil, a wipe that is clean.

Advantages of 304 stainless steel applications with oven liners

In addition to superior performance, 304 stainless steel in the appearance of modernity and a sense of seniority, in line with the current consumer kitchen appliances products “beautiful + practical” double pursuit. Some high-end brands will be 304 stainless steel as the core selling point of the product, through the upgrading of the liner material to enhance the positioning of the machine. Of course, there are other materials such as enamel, 430 stainless steel, galvanized sheet, etc. are used in some of the oven liner, but compared with 304 stainless steel, they are in the corrosion resistance, service life, high temperature performance and food contact safety are obvious gaps. For example, although 430 stainless steel is inexpensive, but poor corrosion resistance, easy to rust; enamel is beautiful, but easy to chipping, cracking, long-term use of the surface layer may fall off.

In summary, 304 stainless steel with its high strength, excellent heat and corrosion resistance, excellent food safety and beautiful appearance characteristics, become the first choice of oven liner material program. It not only enhances the durability and cleaning convenience of the oven, but also protects the user's food safety, which is an ideal material indispensable in modern kitchens.