Ningbo Huali Steel Co., Ltd is a fully developed manufacturer of Grade 1 Titanium Coil for structural parts in China. Ningbo Huali Steel also produces grade 1 and grade 2 Titanium coils/strips/foils. Our materials have a good price advantage with superior quality and cover most of the European,Latin American, Southeastern markets. .

Ningbo Huali Steel delivers foils, strips and coils of pure Grade 1 Titanium coil for structural parts and Grade 2.

Grade 1 Titanium coil for structural parts (UNS R50250, corresponding to domestic grade TA1/GR1) is a high-purity industrial pure titanium material with a titanium content of ≥99.6% and impurity elements (such as iron, oxygen, carbon, nitrogen, etc.) strictly controlled at an extremely low level. Its core characteristics are low density, high strength, corrosion resistance, high temperature resistance and good biocompatibility. It is a key material for lightweight structural design in the aerospace industry.

| GRADE | Chemical Composition | ||||||

| Fe | O | N | C | H | Other Elements | Ti | |

| % | % | % | % | % | % | % | |

| Grade 1 | ≤0.15 | ≤0.12 | ≤0.05 | ≤0.06 | ≤0.013 | ≤0.40 | Balance |

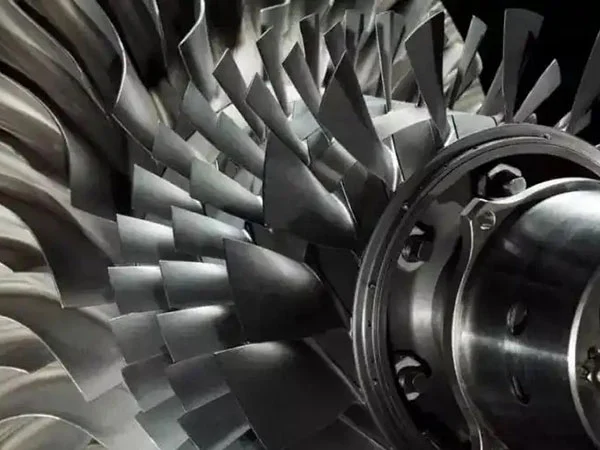

Grade 1 Titanium Coil for structural parts has a balance of light weight and high strength, extreme environment resistance, thermal stability and fatigue resistance, and processing adaptability. The density of Grade 1 Titanium Coil for structural parts is 4.51g/cm³ (only 60% of steel), which significantly reduces the launch mass of spacecraft. The tensile strength reaches 350MPa (50, 000psi), and the elongation is ≥35%, which can withstand extreme mechanical loads. It forms a dense oxide film (TiO₂) in seawater, wet chlorine, strong acids and alkalis, and the corrosion rate is lower than 1/10 of stainless steel. The melting point is 1670℃, and the short-term working temperature can reach 600℃, which is suitable for the hot end parts of rocket engines. It still maintains toughness in a liquid hydrogen environment of -253℃, and is suitable for deep space probe fuel systems. The low thermal expansion coefficient of Grade 1 Titanium Coil for structural parts is 9.7×10⁻⁶/℃ (20-100℃), which reduces the deformation stress caused by temperature changes. Under alternating loads (such as the vibration environment of rocket engines), the fatigue life is 3-5 times higher than that of aluminum alloy. It can be made into 0.01-6.0mm thick coils through cold rolling, hot rolling, annealing and other processes to meet the needs of complex structural parts.

Grade 1 Titanium Coil for structural parts is a metal that forms an extremely resistant oxide protective layer when exposed to air. This property and its low density (weight) make titanium the preferred choice for applications in medicine, aerospace, and even motor racing.

Its good corrosion resistance also makes titanium the ideal material for heat exchangers in the chemicals industry, e.g. for desalination plant and other saltwater proof components in shipbuilding, plant construction, and boiler engineering.

Our dedicated loading team ensures meticulous handling of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods (Grade 1 Titanium Coil for structural parts) arrive in safe condition.

Certificates: ISO9001, SGS, MTC...