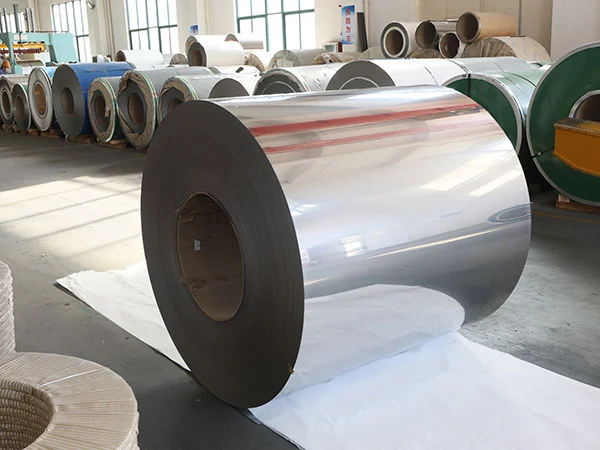

Ningbo Huali Steel Co., Ltd is a Chinese supplier of Grade 2 Titanium Alloy Coil, specializing in grade 1 and grade 2 Titanium coils/strips/foils. Our materials have a good price advantage with superior quality and cover most of the European,Latin American, Southeastern markets.

Grade 2 titanium alloy coil (UNS R50400, TA2) is a commercially pure titanium alloy material. Based on pure titanium, it significantly improves the strength and processing performance of the material while maintaining the excellent corrosion resistance of high-purity titanium through the optimized ratio of trace alloying elements (such as iron and oxygen). Its density is only 4.5g/cm³ (about 60% of steel) and its melting point is about 1670℃. It has both lightweight and high temperature resistance characteristics. It is a key structural material in the fields of aerospace, marine engineering, medical equipment, chemical equipment, etc.

| GRADE | Chemical Composition | ||||||

| Fe | O | N | C | H | Other Elements | Ti | |

| % | % | % | % | % | % | % | |

| Grade 2 | ≤0.20 | ≤0.18 | ≤0.05 | ≤0.06 | ≤0.013 | ≤0.40 | Balance |

Grade 2 titanium alloy coil has a balance of high strength and light weight, excellent corrosion resistance, excellent processing and welding performance, biocompatibility and non-magnetic.

345-485MPa (much higher than 240MPa of Grade 1 titanium), yield strength ≥275MPa, elongation 20%-40%, can withstand complex mechanical loads. A dense titanium oxide (TiO₂) passivation film is formed on the surface, which is resistant to pitting and crevice corrosion in seawater and salt spray, and is suitable for offshore platforms and ship parts. Resistant to weak acid and weak alkali corrosion, the heat exchanger in the chlor-alkali industry uses TA2 coils, and the maintenance cost is reduced by 40%. The oxidation resistance reaches 600℃, which is suitable for high temperature conditions of oil drilling equipment.

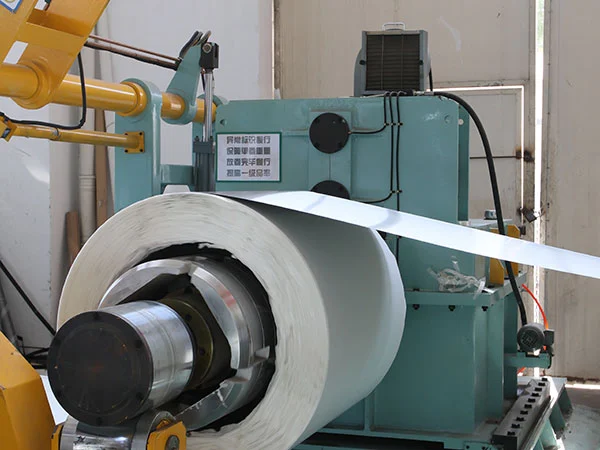

Complex structural parts, such as thin-walled parts of satellite shells (thickness 0.2-1.0mm), can be formed through cold rolling, stretching, stamping and other processes. The strength of the argon arc welding joint is close to that of the parent material. The Long March series rocket fuel tank adopts TA2 welding process, and the airtightness compliance rate is 100%. Solution treatment (750-850℃) can eliminate processing stress. Annealed pipes are used in aircraft hydraulic systems, and fatigue life is increased by 30%.

Grade 2 titanium alloy coil is Non-toxic, non-magnetic, and highly compatible with human tissues, it is widely used in artificial joints, bone screws, and spinal fusion devices, with a postoperative infection rate of less than 0.5%.

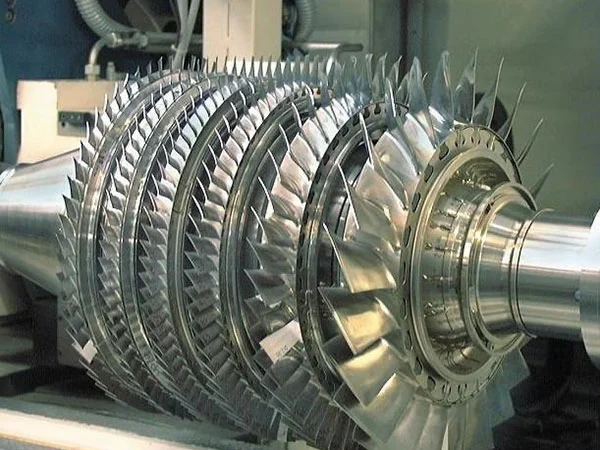

Grade 2 titanium alloy coil can be used for aircraft frames, engine casings, and lunar module frames. For example, the high-pressure gas cylinders of the Tianwen-1 Mars rover are welded with TA2 coils, which reduces weight by 40% and withstands a pressure of 35MPa. It can also be used for offshore platform support structures, ship propeller sleeves, and deep-sea equipment. TA2 coils have been in service in the South China Sea environment for 10 years without corrosion, and their lifespan is three times that of stainless steel. Artificial hip and knee joints use TA2 porous structures to promote bone cell growth and shorten the postoperative recovery period by 20%. Grade 2 titanium alloy coil can also be used in reactors and heat exchangers, mobile phone and watch accessories, and many other fields.

Grade 2 titanium alloy coil is a metal that forms an extremely resistant oxide protective layer when exposed to air. This property and its low density (weight) make titanium the preferred choice for applications in medicine, aerospace, and even motor racing.

Its good corrosion resistance also makes titanium the ideal material for heat exchangers in the chemicals industry, e.g. for desalination plant and other saltwater proof components in shipbuilding, plant construction, and boiler engineering.

Our dedicated loading team ensures meticulous handling of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods ( Grade 2 titanium alloy coil) arrive in safe condition.

Certificates: ISO9001, SGS, MTC...