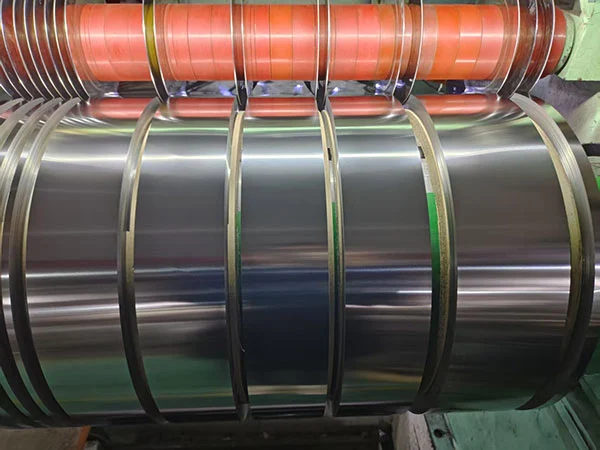

Ningbo Huali Steel Co., Ltd is a leading supplier of 1.4725 Cold Rolled FeCrAl Alloy Coil in China, specializing in producing 1.4725/Cral4/0Cr18Al4, 1.4767/Cral6/0Cr21Al6, 0Cr15Al5, etc. With 20 years of professional experience, we offer a wide range of grades, including 301, 304, 304L,370, 305, 309s, 310s, 316, 316L, 317, 321, 409, 430, 410S and more.

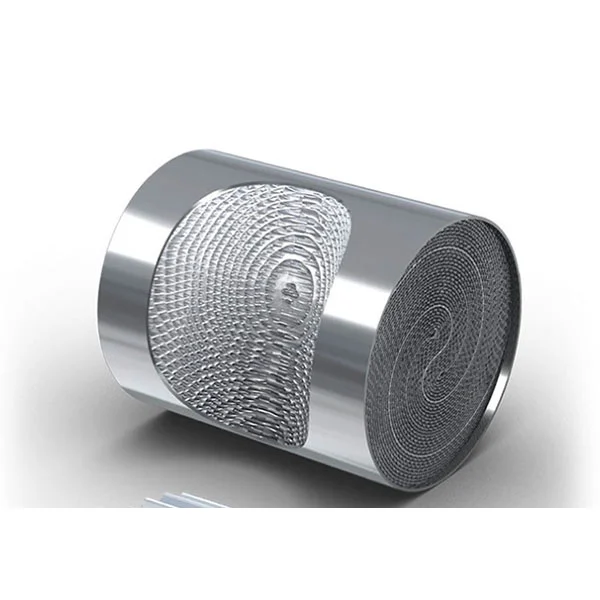

1.4725 cold rolled FeCrAl alloy coil is a heat-resistant alloy of FeCrAl series, whose main components include iron, chromium, aluminum and other elements, and is made into high-precision coils through cold rolling process. This material is known for its excellent oxidation resistance, high temperature strength and corrosion resistance, and is suitable for long-term stable operation in extreme high temperature environments. 1.4725 cold rolled FeCrAl alloy coil is commonly used in various electric heating elements such as electric furnace wire, electric heating tube, three-way catalytic converter of automobile exhaust emission components, and for manufacturing engine components in aerospace, etc.

| GRADE | Chemical Composition | |||||

| Cr | Si | AI | Cr | RareEarth Elements | Fe | |

| 0Cr18Al4 | max0.05 | ~0.3 | 3.5-4.5 | ~17.5 | 0.02-0.10 | balance |

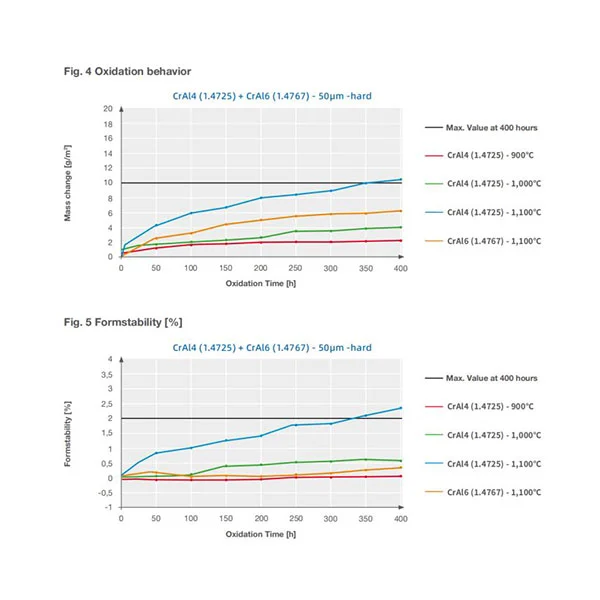

Ningbo Huali Steel produces and supplies 1.4725 cold rolled FeCrAl alloy coil that retain their geometry and corrosion resistance at temperatures up to 1200°C. It has excellent high temperature resistance and can maintain stable performance in high temperature environment. With a minimum thickness of 0.025 mm and a melting point of around 1500°C, this metal is a metallurgical masterpiece that only very few metals in the world can match. A dense oxide film will form on the surface of the alloy at high temperature, which can effectively prevent further oxidation reaction, thus extending the service life of the material. 1.4725 cold rolled FeCrAl alloy coil has a high resistivity, which enables it to efficiently convert electrical energy into thermal energy in electrothermal applications. 1.4725 cold rolled FeCrAl alloy coil has good cold forming performance at room temperature, and can be easily processed.

Commonly used in catalytic converters, diesel particulate filters as well as fuel cells and electrolyzers, resistors, e-cigarettes, heating elements, etc.

1.4725 cold rolled FeCrAl alloy coil is a high-performance alloy material, mainly composed of iron, chromium, aluminum and other elements. Maximum temperatures are as follows: CrAl4/1.4725 up to 1.000°C, CrAl6/1.4767 up to 1.200°C.

Our dedicated loading team ensures meticulous handling of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods (1.4725 cold rolled FeCrAl alloy coil) arrive in safe condition.

Certificates: ISO9001, SGS, MTC...