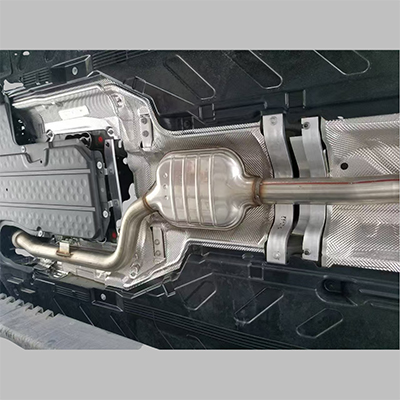

As a key thermal protection component, the automotive heat shield needs to operate stably for a long time in a high temperature and corrosive exhaust gas environment. As mainstream materials, the performance difference between 304 stainless steel and 321 stainless steel directly affects the heat insulation effect and equipment life.

1. The basic advantages of 304 stainless steel in heat shields

Corrosion resistance and cost-effectiveness

304 stainless steel forms a dense oxide film with a classic formula of 18% chromium + 8% nickel, and performs well in normal temperature and medium and low temperature exhaust gas environments. Its resistance to corrosion by dilute acids, dilute alkalis and organic solvents is suitable for conventional fuel vehicle exhaust pipes.

Processability and surface treatment

The work hardening index (n value) of 304 is 0.45, which is better than 0.38 of 321, making it more advantageous in complex processes such as deep stamping and spinning. The surface roughness after electrolytic polishing can reach Ra0.05μm, meeting the stringent requirements for finish of automotive exterior parts.

Low temperature strength and impact resistance

304 maintains good toughness in the range of -196℃ to 400℃, and has outstanding impact load resistance. A collision test shows that the 304 heat shield did not break in an 80km/h rear-end collision, effectively protecting the rear components.

2. Technological breakthroughs in 321 stainless steel in high temperature insulation

Titanium stabilization to resist intergranular corrosion

321 adds 0.5% titanium to form TiC compounds to inhibit the precipitation of chromium carbide, fundamentally solving the problem of high temperature intergranular corrosion.

High temperature strength and creep performance

The endurance strength of 321 at 600℃ reaches 145MPa, which is 22% higher than that of 304; the creep rupture time is extended by more than 3 times.

Weldability and heat treatment optimization

The weld metal elongation of 321 reaches 35%, which is 5 percentage points higher than that of 304, and the sensitivity of welding hot cracks is reduced by 40%. Its solid solution treatment requires quenching at 1050-1100℃ to ensure that the titanium element is fully dissolved. A new energy vehicle company uses laser welding of 321 heat shields, with weld strength reaching 95% of the parent material, meeting the 800°C high-temperature exhaust gas treatment requirements of hydrogen fuel cell vehicles.

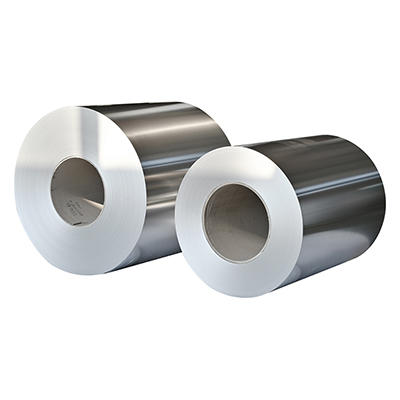

At Ningbo Huali Steel, you can find stainless steel 304 and 321 materials that meet your requirements.

Ningbo Huali Steel provides high-quality 304 and 321 stainless steel coils and strips that meet different industry standards. With years of experience and commitment to customer satisfaction, the materials we provide ensure reliability, performance and value. Visit our website www.bowasteel.com for more information and welcome to buy 304 and 321 stainless steel materials from us!