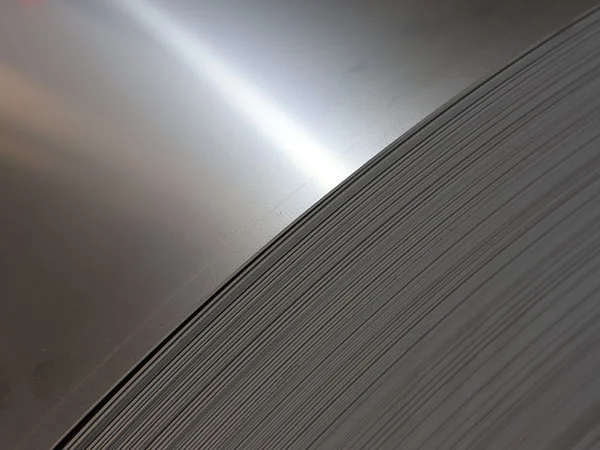

As a leading manufacturer of EN1.4539 High Temperature Alloy Foil, Ningbo Huali Steel Co., Ltd has a 20-year’s experience in producing cold-rolled stainless steel coils/strips/foils/sheets in China. Our product range includes 304, 301, 321, 310s, 304L, 316L, 410s, 430, 904L and more. Get inquiry now if you have any inquiries!

EN1.4539 high temperature alloy foil is a foil product made of 1.4539/904L super austenitic stainless steel material. EN1.4539 high temperature alloy foil is widely used in many industrial fields due to its excellent corrosion resistance, oxidation resistance and mechanical properties. After being made into foil, EN1.4539 high temperature alloy foil plays an important role in high-end application scenarios with its unique performance advantages.

The main chemical composition of EN1.4539 high temperature alloy foil includes high content of chromium (Cr), nickel (Ni), molybdenum (Mo) and copper (Cu). Specifically, the chromium content is between 19.0% and 23.0%, the nickel content is between 23.0% and 28.0%, the molybdenum content is between 4.0% and 5.0%, and the copper content is between 1.0% and 2.0%. In addition, it also contains a small amount of carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S) and other elements, and the content is controlled within a reasonable range to ensure the overall performance of the material.

At Ningbo Huali Steel, we can achieve a minimum thickness of 0.01mm and control the minimum tolerance of +/-0.002mm. Provide customized services and provide the best service according to each customer's requirements.

| GRADE | Chemical Composition | ||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | |

| % | % | % | % | % | % | % | % | % | |

| 904L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 23.0-25.0 | 18.0-20.0 | 3.0-4.0 | 4.0-5.0 |

EN1.4539 high temperature alloy foil has good corrosion resistance, oxidation resistance, high strength and ductility, excellent machinability and weldability, and resistance to intergranular corrosion.

EN1.4539 high temperature alloy foil performs well in a variety of corrosive media. It has good corrosion resistance to dilute sulfuric acid, phosphoric acid, inorganic acids and most organic acids, and can maintain complete corrosion resistance in dilute sulfuric acid at a concentration range of 0-100% and a temperature of up to 95°F (35°C). Its chloride stress corrosion cracking resistance is significantly better than that of stainless steel such as 316L.

In high temperature environments, EN1.4539 high temperature alloy foil can form a dense oxide film, which effectively prevents further oxidation reactions and protects the material from oxidation damage.

The alloy foil has high tensile strength and yield strength and can withstand large mechanical stresses. At the same time, it also has good ductility, which is convenient for various processing and forming operations.

EN1.4539 high temperature alloy foil is easy to weld and process. It can be welded by various methods such as manual arc welding. In terms of processing, it can be processed by cold forming, hot forming and other methods to meet the requirements of different shapes and sizes.

Since the carbon content of EN1.4539 high temperature alloy foil is very low (maximum 0.020%), there will be no carbide precipitation under general heat treatment and welding, thus eliminating the risk of intergranular corrosion.

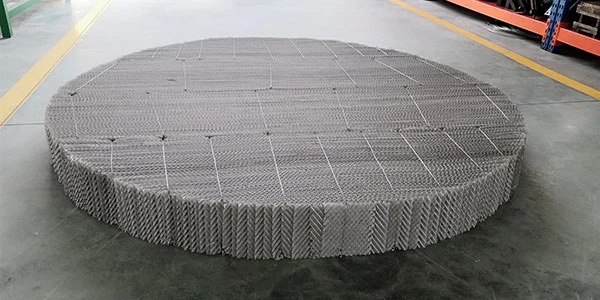

EN1.4539 high temperature alloy foil is usually used in the petrochemical industry, such as heat exchangers, reactors, pipelines, valves, pumps and other key components. In the field of marine engineering, it can be used to manufacture parts for ships, seawater treatment equipment, offshore platforms and other equipment. In the power generation industry, it can be used to manufacture the tower body, flue, baffle plate, internal parts, spray system and other parts of the absorption tower.

Ningbo Huali Steel has introduced advanced machinery from abroad, equipping its production lines with top-tier manufacturing equipment. Equipment include the American imported twenty series Sendzimir high precision reversible mill, pulling and straightening machines, continuous bright annealing furnace, steel coil cleaning lines as well as slitting machines.

As for packaging, we offer standard packaging (waterproof paper and steel belt packing) and wooden box packaging, as well as customized packaging solutions.

Our dedicated loading team takes god care of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods (pEN1.4539 high temperature alloy foil) arrive in perfect condition.