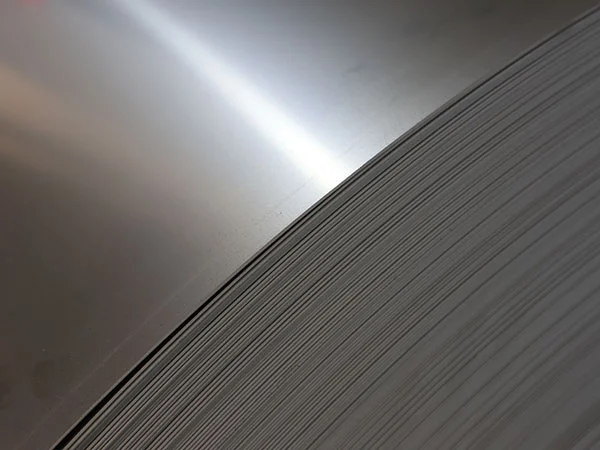

As a leading manufacturer of Precision Aisi 904L High Temperature Alloy Foil, Ningbo Huali Steel Co., Ltd has a 20-year’s experience in producing cold-rolled stainless steel coils/strips/foils/sheets in China. Our product range includes 304, 301, 321, 310s, 304L, 316L, 410s, 430, 904L and more. We are committed to reducing raw material costs for you while delivering superior quality materials at the best prices and designing our unique solutions to meet your specific needs.

Precision Aisi 904L high temperature alloy foil is a super austenitic stainless steel. The combination of nickel, chromium and molybdenum makes it perform well in a variety of corrosive media, especially in strong acidic environments and environments containing chloride ions. Precision Aisi 904L high temperature alloy foil is widely used in chemical, marine engineering, energy, pharmaceutical and food industries for its excellent corrosion resistance, good high temperature performance and excellent processing and welding performance. Despite its high cost, its reliability and versatility in harsh environments make it the material of choice for many high-end applications. Choosing precision Aisi 904L high temperature alloy foil means choosing excellent quality and reliable performance, providing all-round protection for your industrial equipment and products.

Precision Aisi 904L high temperature alloy foil has good corrosion resistance, high temperature performance and excellent processing and welding performance.

At Ningbo Huali Steel, we can achieve a minimum thickness of 0.01mm and control the minimum tolerance of +/-0.002mm. Provide customized services and provide the best service according to each customer's requirements.

| GRADE | Chemical Composition | ||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | |

| % | % | % | % | % | % | % | % | % | |

| 904L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 23.0-25.0 | 18.0-20.0 | 3.0-4.0 | 4.0-5.0 |

The chemical composition of precision Aisi 904L high temperature alloy foil includes high content of nickel (23.0-28.0%), chromium (19.0-23.0%) and molybdenum (4.0-5.0%), as well as a moderate amount of copper (1.0-2.0%). This combination of ingredients makes it perform well in strong acidic environments and environments containing chloride ions. Its pitting resistance equivalent (PREN) is as high as 34-36, which is much higher than ordinary stainless steel, and it performs well in strong acids such as sulfuric acid, phosphoric acid, and acetic acid.

Precision Aisi 904L high temperature alloy foil can still maintain good mechanical properties in oxidizing or reducing environments below 400°C. Its yield strength is ≥220MPa, tensile strength is ≥490MPa, and elongation is ≥35%, with good toughness and strength.

Precision Aisi 904L high temperature alloy foil has good cold working properties and can be processed by cold rolling, drawing and other processing operations, but it has a strong tendency to work hardening and requires intermediate annealing to alleviate work hardening. It has good welding performance, is not prone to intergranular corrosion, and is suitable for TIG, MIG and other welding methods.

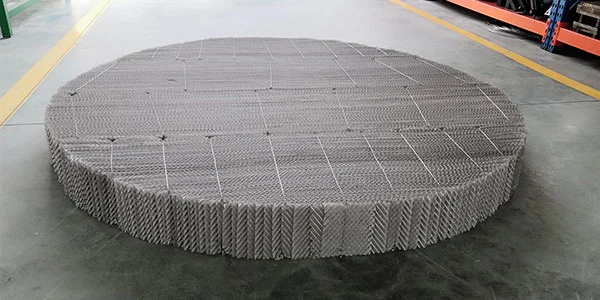

Precision Aisi 904L high temperature alloy foil is widely used in acidic environment equipment in the chemical and petrochemical industries, such as pipelines, heat exchangers, and storage tanks in the production of sulfuric acid and phosphoric acid. In marine engineering, precision Aisi 904L high temperature alloy foil is used to manufacture seawater treatment systems, seawater desalination equipment, and offshore platform components. It is also widely used in the energy industry, such as flue gas desulfurization devices (FGD) and corrosion-resistant components of nuclear power equipment. The non-magnetic and non-toxic nature of precision Aisi 904L high temperature alloy foil makes it an ideal choice for processing equipment, reactors, and pipelines in the pharmaceutical and food industries.

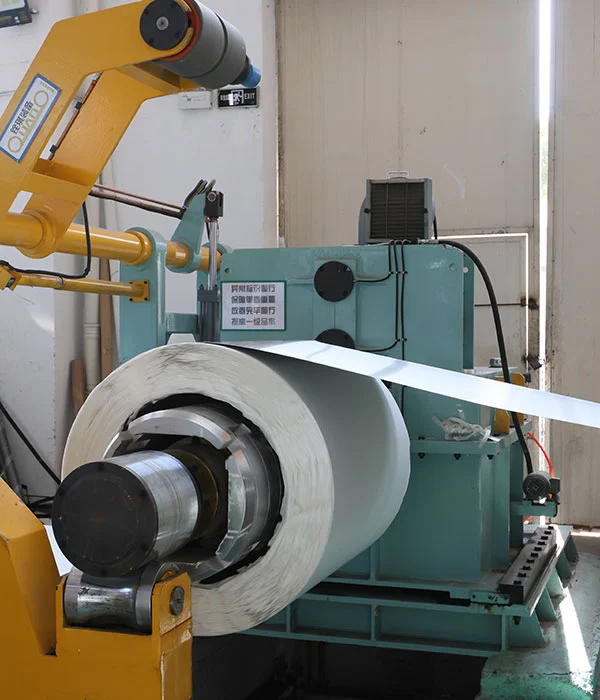

Ningbo Huali Steel has introduced advanced machinery from abroad, equipping its production lines with top-tier manufacturing equipment. Equipment include the American imported twenty series Sendzimir high precision reversible mill, pulling and straightening machines, continuous bright annealing furnace, steel coil cleaning lines as well as slitting machines.

As for packaging, we offer standard packaging (waterproof paper and steel belt packing) and wooden box packaging, as well as customized packaging solutions.

Our dedicated loading team takes god care of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods (precision Aisi 904L high temperature alloy foil) arrive in perfect condition.