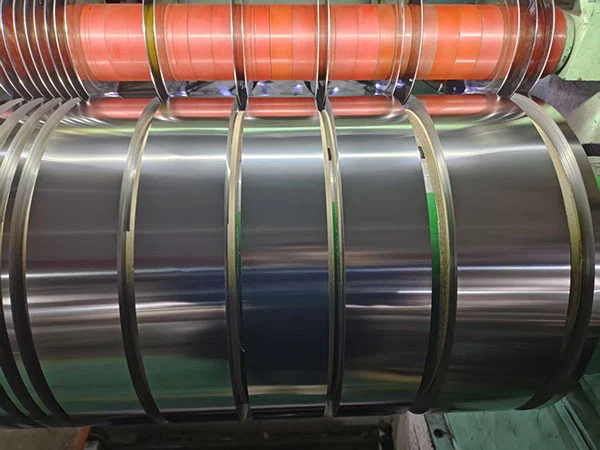

Ningbo Huali Steel Co., Ltd. focus on precision stainless steel materials. It has production lines such as slitting units, rolling mills, annealing furnaces, etc. The raw materials are mainly purchased from well-known steel mills such as TISCO, Baosteel, and Posco, South Korea. Ningbo Huali Steel takes precision stainless steel strip processing as its core advantage, and its technology focuses on ultra-thin, high hardness and special surface treatment fields to serve the high-end manufacturing industry. In addition, the company has made long-term, continuous and high-intensity investment in EN1.4725 FeCrAl Alloy Strip.

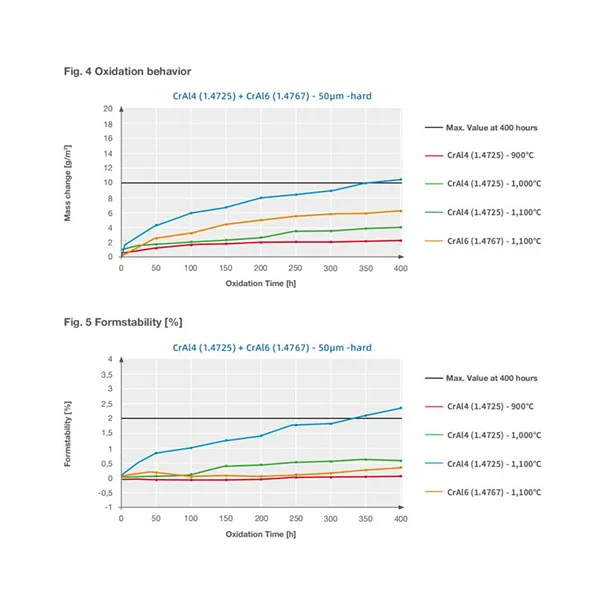

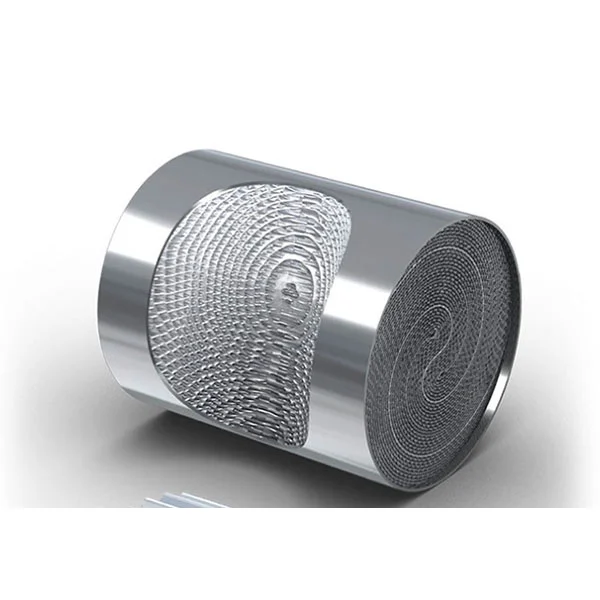

EN1.4725 FeCrAl Alloy Strip is an electric heating material with iron, chromium and aluminum as the main components. It has the characteristics of high resistivity, small temperature coefficient of resistance, good oxidation resistance and high operating temperature. Its maximum operating temperature can reach 1400℃, and the Al₂O₃ oxide film formed on the surface significantly improves the high-temperature oxidation resistance. EN1.4767 FeCrAl alloy coil is light in weight and low in cost, and is suitable for industrial electric furnaces, household appliances and other scenarios. By optimizing the preparation process, the high-temperature brittleness problem of traditional materials is solved and the service life is extended.

| GRADE | Chemical Composition | ||||||||

| Cr | AI | Cr | AI | S | P | Mn | Ni | N | |

| 0Cr21AI6 | 19.0-22.0 | 5.0-7.0 | 19.8946 | 5.4475 | 0.001 | 0.014 | 0.097 | 0.1099 | 0.0057 |

1) High temperature characteristics

EN1.4767 FeCrAl alloy coil is generally used at a temperature of 1400°C, and special types (such as 0Cr21Al6Nb, 0Cr27Al7Mo2) can withstand temperatures up to 1500°C (until 2025). The oxidation weight gain rate at high temperatures is less than 1.5g/m²·h, and the service life is 2-4 times that of nickel-chromium alloys.

2) Lightweight and economical characteristics

The density of EN1.4767 FeCrAl alloy coil is about 15% lower than that of nickel-chromium alloy, and the same component can save 20% of materials. The raw materials are scrap iron and scraps, and the cost is reduced by 20%-35%.

3) Environmental adaptability

EN1.4767 FeCrAl alloy coil’s tolerance in sulfur-containing atmosphere is better than that of nickel-chromium alloy, and its anti-carburization performance is improved by 50%. Rare earth elements are added to refine the grains and reduce inclusions by 40%.

1) Industrial heating equipment

EN1.4767 FeCrAl alloy coil is widely used in metallurgical machinery, ceramic kilns, glass melting and other scenarios, the component surface load reaches 1.5-2.0W/cm². Used for cracking heating above 1400℃ in petrochemical reactors.

2) Civilian appliances

EN1.4767 FeCrAl alloy coil is widely used in household appliances such as electric ovens and electric irons, the heating efficiency is increased by 30% with infrared radiation. Data from 2025 shows that the maximum temperature resistance of 0.2-5.5mm wire is 1500℃.

The alloy has defects such as low high temperature strength and easy deformation. By adding titanium and rare earth to improve the grain boundary strength, the elongation is greater than 12%. The vacuum melting process increases the toughness by 25% and the fatigue strength by 40%. The 2024 patent uses nano-alumina coating to extend the life of 1300℃ to 3000 hours.

The company has established a full-process control system, focusing on the following core links: 1. Precise control of ingredients 2. Organization and performance optimization 3. Full-process testing and verification 4. Zero-tolerance strategy for defects 5. Traceability management. Each batch of materials is bound to the melting furnace number, rolling process parameters and test report (in compliance with the ISO 9001 system), realizing two-way traceability from raw materials to finished products.