Ningbo Huali Steel Co., Ltd. is among China's largest manufacturers of CrAl4 FeCrAl Alloy Strip. Our high-temperature alloy and stainless steel coil/strip export countries are all over the world, mainly at Asia, North America, South America, Europe and other regions.

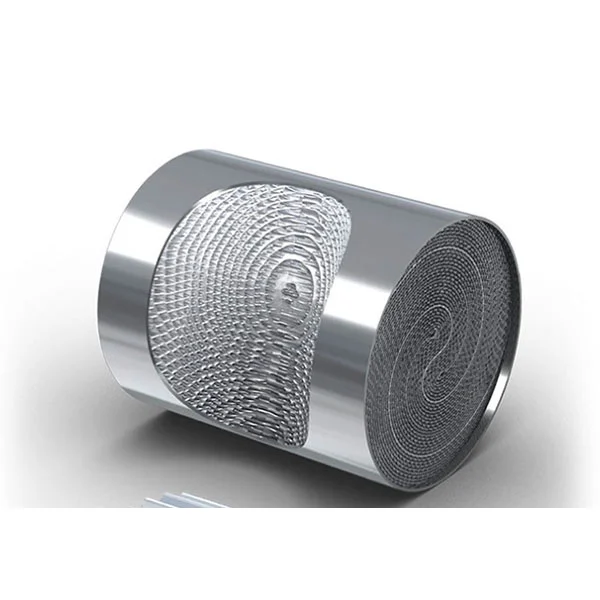

CrAl4 FeCrAl Alloy Strip is a specialized material, primarily composed of iron, chromium, and aluminum. Crafted with a sophisticated formula and advanced rolling techniques, it merges the robust mechanical properties of iron-based alloys with the exceptional high-temperature resistance provided by chromium and aluminum, making it highly valuable in diverse high-temperature industrial applications.

| GRADE | Chemical Composition | |||||

| Cr | AI | Nb | AI | Fe | P | |

| Cr18AI4 | 21.0-23.0 | 5.0-7.0 | 0.5 | 5.4475 | Moderate Amount | Moderate Amount |

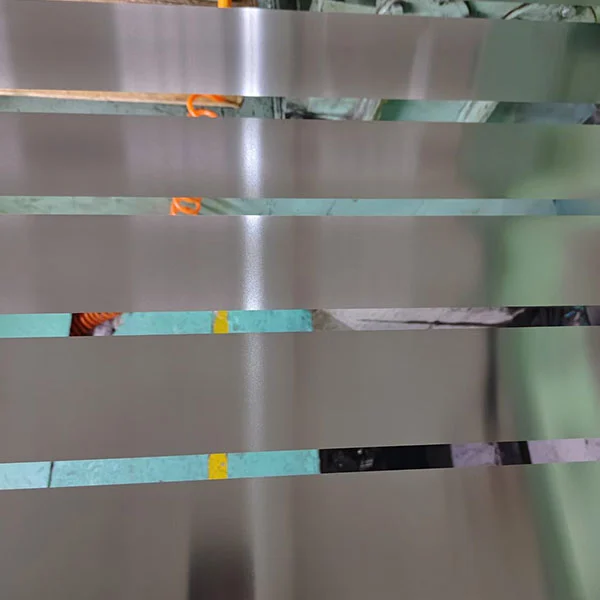

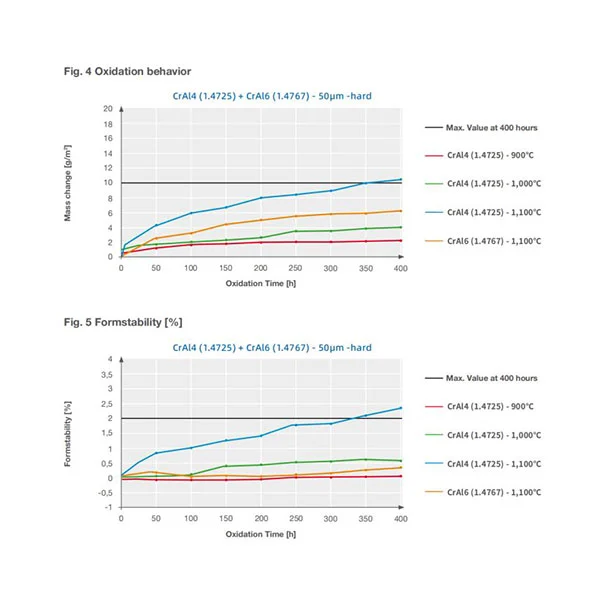

The CrAl4 FeCrAl alloy strip is a ferro-chromium-aluminum alloy material with iron (Fe) as the matrix, containing chromium (Cr), aluminum (Al), and a small amount of other elements. Its core characteristics lie in its high-temperature stability and oxidation resistance. The addition of chromium elements endows the alloy with excellent corrosion resistance and high-temperature strength, while aluminum can form a dense aluminum oxide protective film on the surface of the material, effectively blocking the further reaction between oxygen and the substrate, allowing it to work stably for a long time at temperatures above 1000℃. In addition, this alloy strip has a low resistivity and good processing performance. It can be rolled into a thin strip form, possessing certain flexibility and mechanical strength, and can meet the forming requirements in complex working conditions. At the same time, its thermal expansion coefficient is low, and it is less likely to deform or crack due to thermal stress when the temperature changes drastically, making it suitable for scenarios with high requirements for dimensional stability.

Based on these characteristics, this CrAl4 FeCrAl alloy strip is widely used in high-temperature heating and corrosion-resistant scenarios. In the industrial heating field, it is often made into resistance heating elements and used in high-temperature furnaces, heat treatment equipment, household appliance heating components, etc., thanks to its high-temperature oxidation resistance, achieving long-term and stable heating; in the automotive and aerospace fields, CrAl4 FeCrAl alloy strip can be used as a high-temperature sealing component, insulation layer or carrier material for catalytic converters, able to withstand the high-temperature environment of engines or combustion chambers; in addition, in environmental protection equipment, its corrosion resistance makes it suitable for smoke gas treatment, high-temperature filtration and other conditions, and can also be used to make the protective shell of high-temperature sensors to ensure the normal operation of components in harsh environments.

CrAl4 FeCrAl alloy strip is a high-performance alloy material, mainly composed of iron, chromium, aluminum and other elements. Maximum temperature for it is as follows: CrAl4/1.4725 up to 1,000°C.

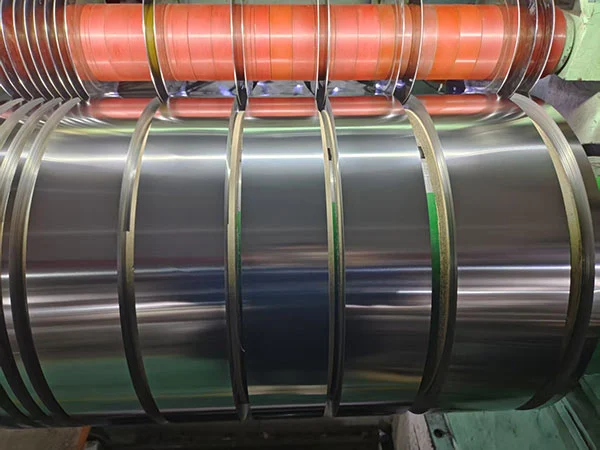

Our dedicated loading team ensures meticulous handling of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods (CrAl4 FeCrAl alloy strip coil) arrive in safe condition.

Certificates: ISO9001, SGS, MTC...