Ningbo Huali Steel Co., Ltd. is a leading manufacturers of DIN 1.4767 FeCrAl Alloy Strip. We specialize in manufcturing a wide range of alloy materials, with more than 15 years of production experience. Equipped with a series of international advanced machines, we have a precise&efficient production line.

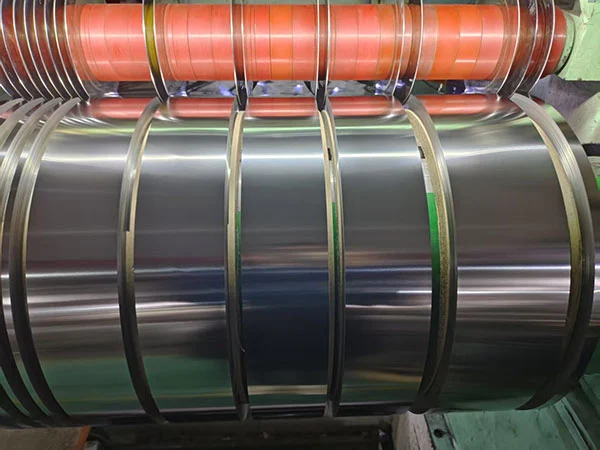

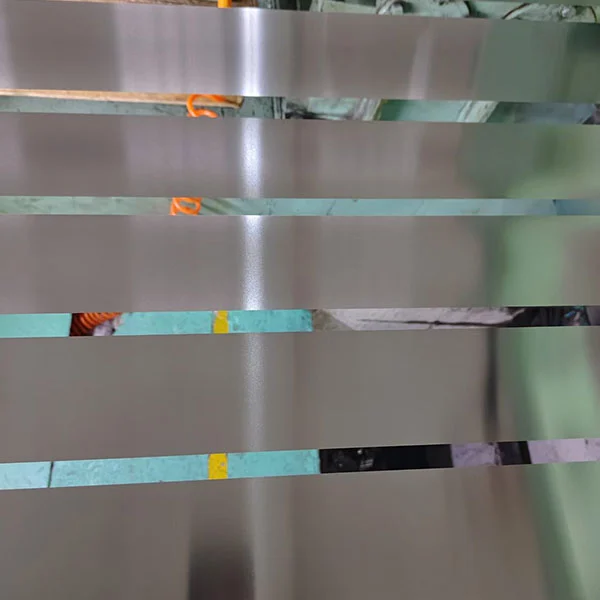

DIN 1.4767 FeCrAl Alloy Strip is a kind of "iron-chromium-aluminum alloy strip" - you can understand it as "a thin long strip made of a mixture of three metals: iron, chromium and aluminum". It usually adopt electric furnace smelting, continuous casting, hot rolling, cold rolling and annealing process. Some products are purified by barium to improve cleanliness and reduce the impact of inclusions on performance. In line with international standards such as DIN 17470, and passed ROHS, SGS, ISO 9001 and other certifications to ensure product quality and environmental protection requirements. Strip thickness is usually between 0.01-3mm, width can reach 1250 mm, size and shape can be customized according to demand.

| GRADE | Chemical Composition | |||||

| Cr | AI | Nb | AI | Fe | P | |

| 0Cr21AI6Nb | 21.0-23.0 | 5.0-7.0 | 0.5 | 5.4475 | Moderate Amount | Moderate Amount |

3.1Material properties and composition

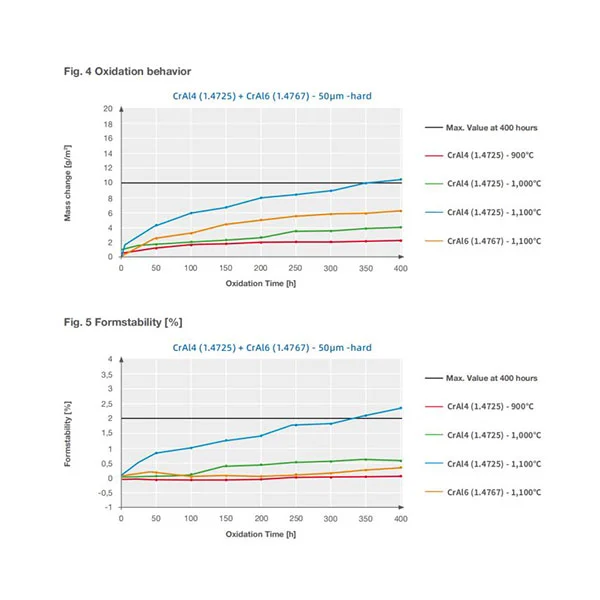

Alloy composition: The main components of DIN 1.4767 FeCrAl alloy strips are iron (Fe), chromium (Cr, about 19-22%) and aluminum (Al, about 5-7%), and the rest is iron. This composition gives the material excellent high-temperature oxidation resistance and high resistivity.

Surface treatment: Usually hydrogen annealed, the surface is bright and soft, and has good molding stability

3.2Applications

Industrial heating equipment

Due to its high oxidation resistance and high temperature resistance, it is widely used in heating parts of electric furnace wires, heating elements, high-temperature furnaces and kilns. For example, DIN 1.4767 FeCrAl alloy strips of grades are often used in high-temperature heat treatment equipment in industries such as ceramics, glass, and steel.

Household appliances

Suitable for heating elements of small household appliances such as hot air guns, ovens, electric heaters, and bread machines, because of its high resistivity and lower cost than nickel-chromium alloys. For example, FeCrAl alloy strips can be made into flat or spiral heating elements to meet the needs of rapid heating.

Automobile exhaust treatment

As a catalytic converter carrier material, the aluminum oxide (Al₂O₃) layer formed on its surface can effectively resist high-temperature corrosion while providing a high specific surface area to support catalyst activity. For example, FeCrAl alloy strips is used in diesel particulate filters to achieve graded filtration and automatic regeneration.

Resistors and electrical components

Due to its stable resistance characteristics, 1.4767 FeCrAl Alloy Strip is often used to manufacture resistor elements in power equipment such as brake resistors and load banks. For example, strips with grades such as 0Cr21Al6Nb can withstand high current loads.

The density of DIN1.4767 FeCrAl Alloy Strip is about 7.16 g/cm³, resistivity is 1.42 Ω・mm²/m at 20°C, and the maximum operating temperature can reach 1250°C. Its linear expansion coefficient is 14.7×10⁻⁶/K, tensile strength is between 630-780 MPa, and elongation exceeds 12%.

Our packaging team will laminate your products and also provide wooden boxes or other packaging to fully protect your products from damage during transportation. In addition, our factory is located in Ningbo, which has the largest port in China, and can guarantee the timeliness of your cargo(DIN1.4767 FeCrAl Alloy Strip)transportation.