En1.4725 FeCrAl Alloy Foil is a kind of high temperature functional material based on Fe-Cr-Al system with excellent oxidation resistance, resistance stability and thermal strength, which is widely used in electric heaters, radiant heating panels, high temperature filters and energy-saving heat energy conversion equipments.Ningbo Huali Steel Co., Ltd has a wealth of experience in machining cold rolled alloys, high precision instruments and professional technology. Ningbo Huali Steel Co., Ltd has rich experience in processing cold rolled alloys with high precision instruments and professional technology, focusing on the processing of En1.4725 FeCrAl Alloy Foil , including 1.4725/Cral4/0Cr18Al4, 1.4767 /Cral6/0Cr21Al6, 0Cr15Al5, etc. A variety of series of alloys.

En1.4725 FeCrAl Alloy Foil is a kind of electrothermal alloy foil with Fe as the matrix and chromium and aluminum as the main alloying elements, which is usually attributed to the FeCrAl series internationally. Its standard name is X10CrAlSi25, in accordance with EN standard no. 1.4725, and it consists mainly of 20% to 25% chromium, about 4% to 6% aluminum, and trace elements of silicon. The alloy rapidly forms a dense alumina film on its surface at high temperatures, which significantly increases its resistance to high-temperature oxidation. Due to its outstanding thermal stability, electrical conductivity and excellent mechanical properties, En1.4725 FeCrAl Alloy Foil are further rolled into foils with thicknesses between 0.02 mm and 0.2 mm for a wide range of industrial applications that require thin, lightweight, flexible, high-temperature work.

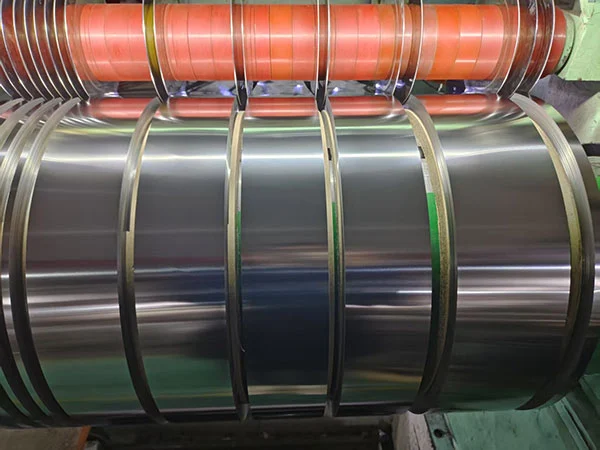

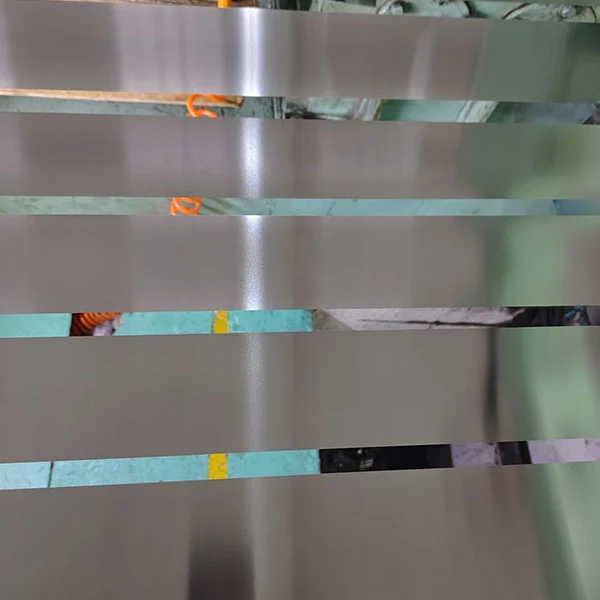

En1.4725 iron chromium aluminum alloy foils are usually manufactured using a combination of high-precision cold rolling and staged intermediate annealing process route. Through multiple alternating rolling and annealing treatment, the thickness, organizational structure and mechanical properties of the foil can be effectively regulated to achieve the predetermined physical state and performance requirements.

| GRADE | Chemical Composition | |||||

| Cr | Si | AI | Cr | RareEarth Elements | Fe | |

| 0Cr18Al4 | max0.05 | ~0.3 | 3.5-4.5 | ~17.5 | 0.02-0.10 | balance |

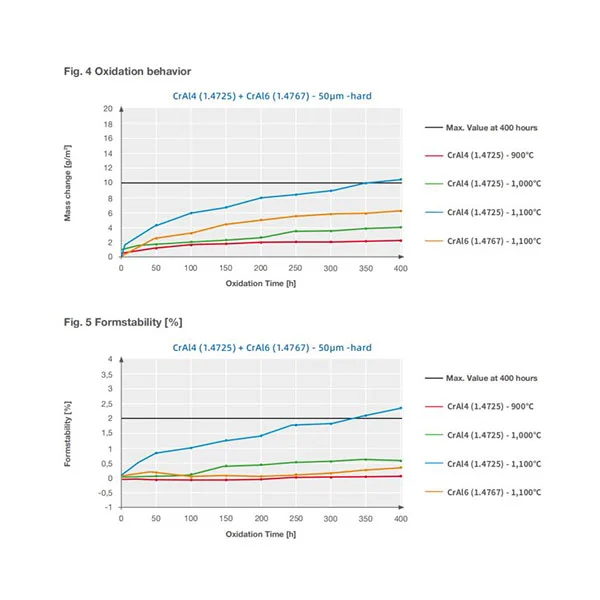

The most important feature of En1.4725 FeCrAl Alloy Foil is their excellent oxidation resistance and thermal stability at high temperatures. At continuous working temperatures of more than 1000°C, a dense and stable protective layer of aluminum oxide is spontaneously generated on the surface of the foil. This protective layer has high chemical stability and adhesion, and effectively inhibits further oxidation of the metal substrate, even under conditions of rapid temperature increase or intense thermal cycling. In addition to its antioxidant properties, En1.4725 FeCrAl Alloy Foil has good resistivity and thermal conductivity. With its high and stable resistivity, it is able to continuously output uniform heat at high temperatures.

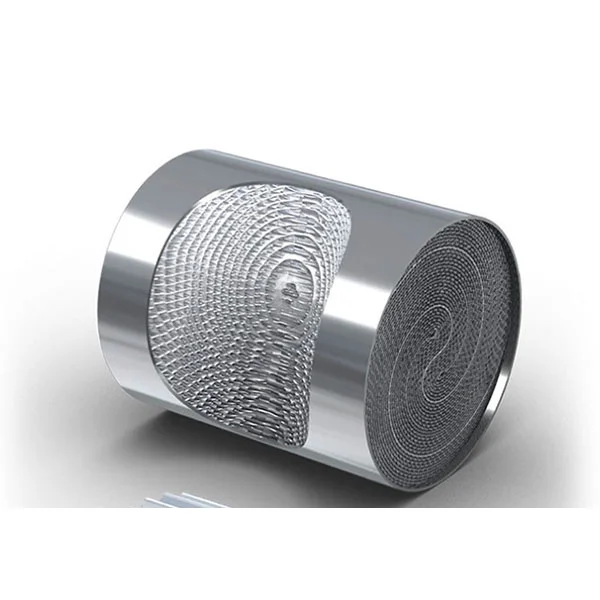

Due to its outstanding thermal stability, electrical conductivity and excellent mechanical properties, En1.4725 FeCrAl Alloy Foil are further rolled into foils with thicknesses ranging from 0.02 mm to 0.2 mm for a wide variety of industrial applications that require thin, lightweight, flexible, and high-temperature work. The foils can not only be processed into desired shapes by stamping, folding, welding, etc., but can also be made into honeycomb structures or porous media for catalyst carriers, filtration membranes, or flue gas treatment systems by micro-porous machining, perforation, and laser cutting. In recent years, En1.4725 FeCrAl Alloy Foil is also widely used in metal catalytic network and air purification equipment, its surface active oxide layer can provide an ideal carrier base for catalytic reaction.

En1.4725 FeCrAl Alloy Foil are usually supplied as precision strips with a thickness of 20 to 200 microns, a density of about 7.2 grams per cubic centimeter, a melting point in the range of 1,350 to 1,500°C, a continuous operating temperature of up to 1,100°C and a short-term temperature resistance of up to 1,250°C. The foils have an electrical resistivity of about 1.4 to 1.5 micro-ohms and a good electrical and thermal conversion efficiency. The foil has a resistivity of about 1.4 to 1.5 micro-ohm, which provides a good electrical and thermal conversion efficiency. With a coefficient of thermal expansion of 14.5 x 10-⁶ per Kelvin, it is suitable for structural design and matching of high-temperature devices.

From the point of view of industry application, En1.4725 FeCrAl Alloy Foil has been widely used in industrial electric heating tape, high-temperature infrared heater, ceramic-metal heating core, automobile exhaust purifier carrier, industrial exhaust gas catalytic treatment network, and household appliances heating film. Especially in the environment that requires thin and light structure, fast response and long-term reliability, its stability is far better than traditional nickel-chromium alloy and other heating materials.