Ningbo Huali Steel Co., Ltd. is one of the largest supplier of Precision 0cr13al4 FeCrAl Alloy Coil in China, specializing in the production of 1.4767/Cral6/0Cr21Al6, 1.4725/Cral4/0Cr18Al4, 0Cr15Al5, etc. Get more details now!

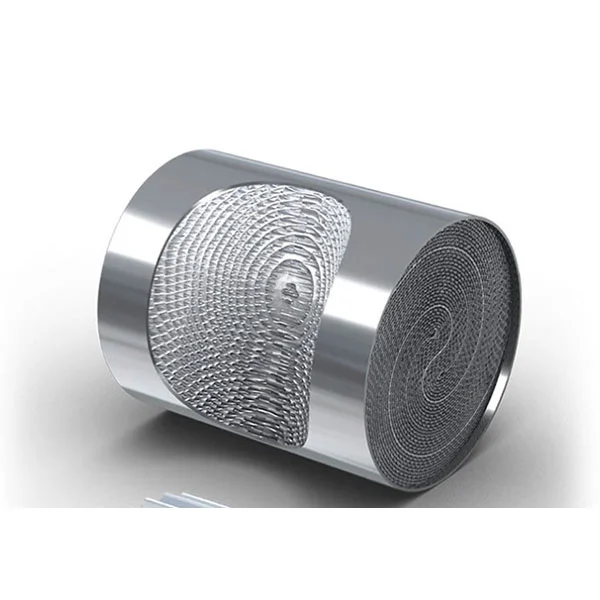

Precision 0cr13al4 FeCrAl alloy coil (0Cr13Al4 iron-chromium-aluminum alloy coil) is a high-performance electric heating and high-temperature structural material with iron as the matrix and the addition of chromium (Cr), aluminum (Al) and other elements. It belongs to the iron-chromium-aluminum (Fe-Cr-Al) alloy system. In its naming rules, "0" means that the carbon content is extremely low (≤0.04%), "13" represents a chromium content of about 13%, and "4" represents an aluminum content of about 4%. By optimizing the ratio of chromium and aluminum, the alloy takes into account high-temperature oxidation resistance, resistance stability and processing performance. It can be used for a long time in a high-temperature environment of 1000℃-1150℃, and is suitable for electric heating elements, industrial furnaces and high-temperature structural parts. Precision 0cr13al4 FeCrAl alloy coil is commonly used in electric heating equipment and industrial furnaces, high-temperature structural parts and protective materials, and the expansion of emerging fields.

| GRADE | Chemical Composition | ||||||||

| C | Si | Cr | AI | S | P | Mn | Ni | N | |

| 1Cr13AI4 | 0.0157 | 0.1068 | 19.8946 | 5.4475 | 0.001 | 0.014 | 0.097 | 0.1099 | 0.0057 |

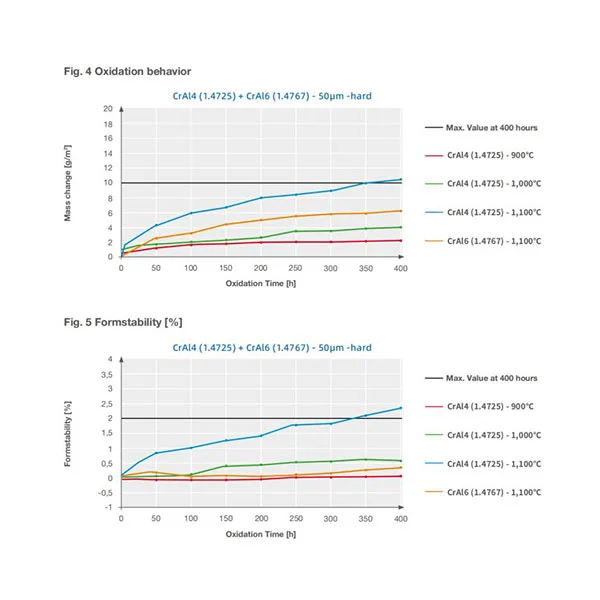

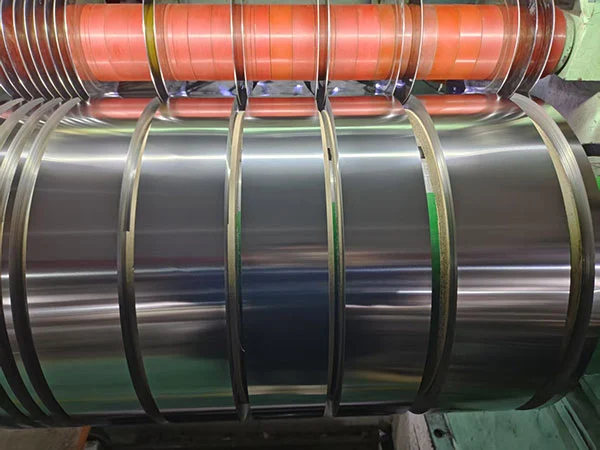

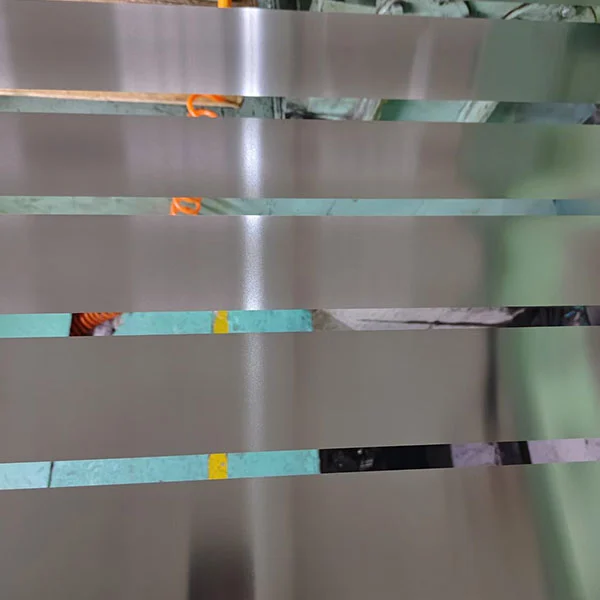

The product characteristics of precision 0cr13al4 FeCrAl alloy coil include high-temperature oxidation resistance and corrosion resistance, high resistivity and thermal stability, light weight, high strength, long life and excellent processing performance. Chromium and aluminum elements form dense Cr₂O₃ and Al₂O₃ oxide films at high temperatures, which effectively prevent oxygen diffusion and slow down the oxidation rate. The resistivity (20℃) is 1.25-1.35 μΩ·m, which is higher than that of ordinary metal materials and can efficiently convert electrical energy into thermal energy. The density is 7.1 g/cm³, which is only 80% of that of nickel-chromium alloy, reducing the weight of the equipment. It can be processed into strips, wires, pipes, etc. through cold rolling, hot rolling, stamping and other processes to meet customized needs.

Precision 0cr13al4 FeCrAl alloy coil are commonly used in heating elements such as electric kettles, electric ovens, electric heaters, core heating components such as heat treatment furnaces, annealing furnaces, muffle furnaces, ceramic sintering furnaces, glass melting furnaces, heat exchangers, high temperature and corrosion resistant lining materials, hydrogen energy equipment, 3D printing and additive manufacturing, etc.

Precision 0cr13al4 FeCrAl alloy coil is a high-performance alloy material, mainly composed of iron, chromium, aluminum and other elements. Maximum temperatures are as follows: CrAl4/1.4725 up to 1.000°C, CrAl6/1.4767 up to 1.200°C.

Our dedicated loading team ensures meticulous handling of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods ( precision 0cr13al4 FeCrAl alloy coil ) arrive in safe condition.

Certificates: ISO9001, SGS, MTC...