As a leading figure in China's alloy manufacturing sector, Ningbo Huali Steel Co., Ltd. is renowned for being one of the largest producers of EN1.4767 FeCrAl alloy coil. Our expertise lies in the production of high - quality alloys such as 1.4767/Cral6/0Cr21Al6, 1.4725/Cral4/0Cr18Al4, and 0Cr15Al5. Leveraging our rich experience in alloy R&D, we are dedicated to the ongoing improvement of the alloys we employ. This commitment has garnered us the trust and preference of manufacturers across the globe in related fields.

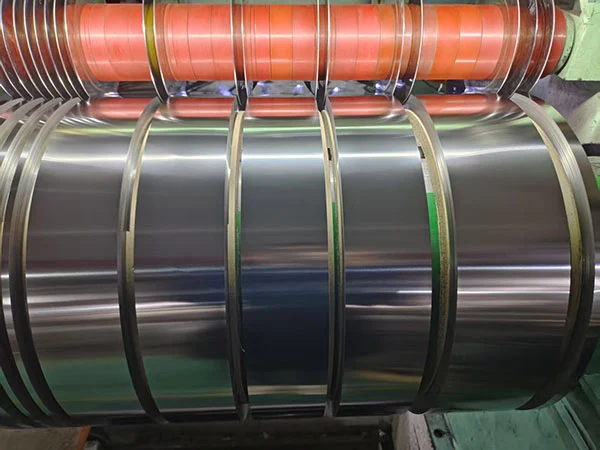

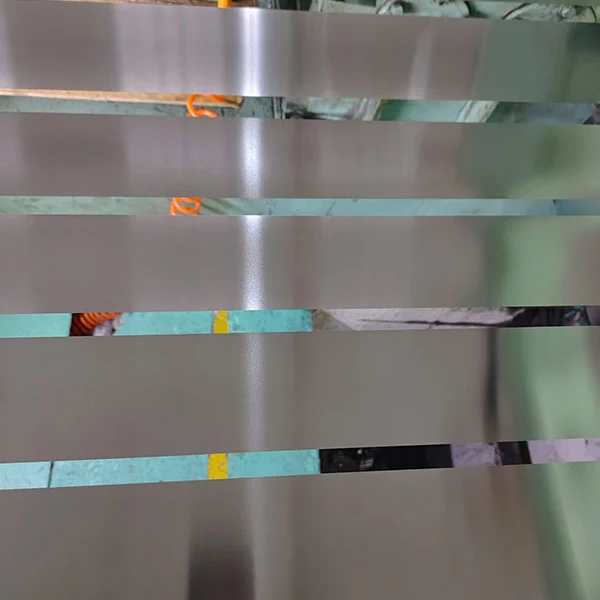

EN1.4767 FeCrAl alloy coil is a metal coil made of iron, chromium and aluminum through advanced production technology. It cleverly combines the unique advantages of iron, chromium and aluminum, and occupies an important position in the field of metal materials. During the production process, the quality of raw materials is strictly controlled, and precise proportions and advanced rolling, annealing and other processes are used to ensure that each roll of iron-chromium-aluminum alloy coil has stable and excellent performance. Its appearance usually presents a unique metallic luster, the surface is flat and smooth, and it has good machinability, which can meet the diverse needs of different customers for coil specifications and shapes.

| GRADE | Chemical Composition | ||||||||

| Cr | AI | Cr | AI | S | P | Mn | Ni | N | |

| 0Cr21AI6 | 19.0-22.0 | 5.0-7.0 | 19.8946 | 5.4475 | 0.001 | 0.014 | 0.097 | 0.1099 | 0.0057 |

EN1.4767 FeCrAl alloy coil has high resistivity, good oxidation resistance, high operating temperature and good processing performance.

EN1.4767 FeCrAl alloy coil has high resistivity, which enables it to generate more heat when current passes through. Compared with traditional resistance materials, the use of FeCrAl alloy coils can reduce the volume and weight of the material at the same power, thereby reducing the overall cost and space occupancy of the equipment. For example, in some small electric heating equipment, the use of FeCrAl alloy coils as heating elements can achieve efficient heating effects in a limited space.

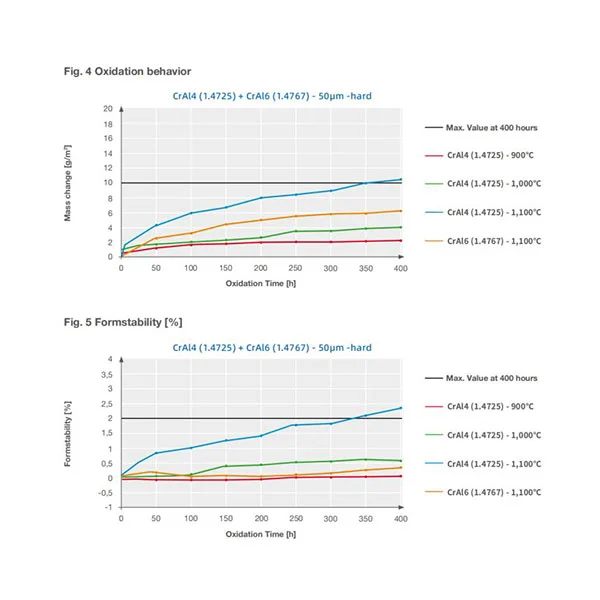

In high temperature environments, a dense aluminum oxide protective film will form on the surface of EN1.4767 FeCrAl alloy coil. This protective film can effectively prevent oxygen from further reacting with the internal metal, thereby greatly improving the material's oxidation resistance.

EN1.4767 FeCrAl alloy coil has a high operating temperature range and can generally work normally at temperatures of 1300℃ or even higher. This feature gives it a wide range of application prospects in the high-temperature industrial field and can meet the requirements of various high-temperature processes for heating materials. It can be used as a reliable heating element.

EN1.4767 FeCrAl alloy coil has good ductility and plasticity.

EN1.4767 FeCrAl alloy coil has a wide range of applications and excellent performance characteristics, and is one of the indispensable important materials in industrial production and scientific and technological development.

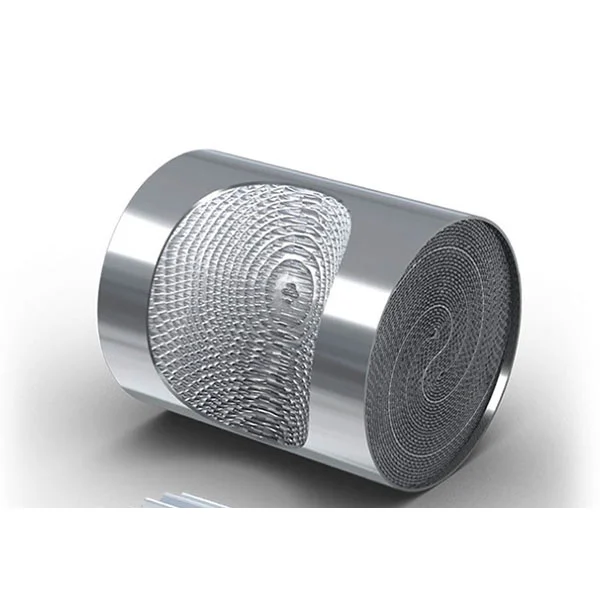

Commonly used in catalytic converters, diesel particulate filters as well as fuel cells and electrolyzers, resistors, e-cigarettes, heating elements, etc.

EN1.4767 FeCrAl alloy coil is a high-performance alloy material, mainly composed of iron, chromium, aluminum and other elements. Maximum temperatures are as follows: CrAl4/1.4725 up to 1.000°C, CrAl6/1.4767 up to 1.200°C.

Our dedicated loading team ensures meticulous handling of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods (EN1.4767 FeCrAl alloy coil) arrive in safe condition.

Certificates: ISO9001, SGS, MTC...