Ningbo Huali Steel Co., Ltd. stands as one of China's foremost manufacturers of 1.4767 cold rolled FeCrAl alloy coils. We specialize in the production of a range of alloys, including 1.4767/Cral6/0Cr21Al6, 1.4725/Cral4/0Cr18Al4, and 0Cr15Al5. With our extensive experience in alloy research and development, we are capable of continuously enhancing the alloys we utilize. As a result, we have earned the favor of manufacturers in relevant industries worldwide.

1.4767 cold rolled FeCrAl alloy coils is a high-performance iron-chromium-aluminum (FeCrAl) heat-resistant alloy, which is made into high-precision coils through precision cold rolling. The material is known for its super strong oxidation resistance, excellent high-temperature stability and excellent mechanical properties. Its chemical composition mainly includes chromium (Cr), aluminum (Al) and iron (Fe), of which chromium and aluminum account for 20% and 5% respectively, and the rest is iron. 1.4767 cold rolled FeCrAl alloy coils has an operating temperature of up to 1200°C and is widely used in industrial equipment in extremely high temperature environments, such as high-temperature furnaces, calcination or combustion kilns.

| GRADE | Chemical Composition | ||||||||

| Cr | AI | Cr | AI | S | P | Mn | Ni | N | |

| 0Cr21AI6 | 19.0-22.0 | 5.0-7.0 | 19.8946 | 5.4475 | 0.001 | 0.014 | 0.097 | 0.1099 | 0.0057 |

1.4767 cold rolled FeCrAl alloy coils has super strong oxidation resistance, excellent high-temperature stability, high resistivity, good machinability and corrosion resistance.

The long-term use temperature can reach 1300°C (short-term tolerance 1400°C), and a dense α-aluminum oxide (Al₂O₃) protective layer is formed on the surface, which effectively prevents high-temperature oxidation and corrosion. High aluminum (5-6%) and chromium (17-19%) content gives the material excellent resistance to thermal fatigue, suitable for scenes with rapid temperature fluctuations. With a resistivity of up to 1.35μΩ·m, it is an ideal choice for electric heating elements (such as heating wires and resistance bands). Cold-rolled tensile strength ≥700MPa, elongation ≥12%, supports secondary processing such as stamping and welding. Resistant to sulfide, chloride and molten salt corrosion, suitable for harsh environments such as chemical industry and glass manufacturing.

1.4767 cold rolled FeCrAl alloy coils has a wide range of applications and excellent performance characteristics, and is one of the indispensable important materials in industrial production and scientific and technological development.

Commonly used in catalytic converters, diesel particulate filters as well as fuel cells and electrolyzers, resistors, e-cigarettes, heating elements, etc.

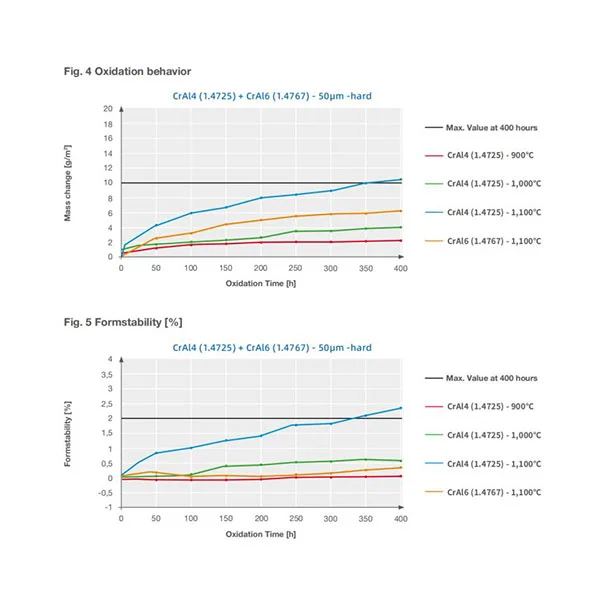

1.4767 cold rolled FeCrAl alloy coils is a high-performance alloy material, mainly composed of iron, chromium, aluminum and other elements. Maximum temperatures are as follows: CrAl4/1.4725 up to 1.000°C, CrAl6/1.4767 up to 1.200°C.

Our dedicated loading team ensures meticulous handling of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods (1.4767 cold rolled FeCrAl alloy coils) arrive in safe condition.

Certificates: ISO9001, SGS, MTC...