Ningbo Huali Steel Co., Ltd. adheres to the business philosophy of "Quality First, Innovation-driven". We are good at manufacturing cold-rolled stainless steel coils and providing high-performance, customized metal material solutions for industries include petrochemicals, energy, shipbuilding, medical products, and high-end equipment manufacturing. We leverage the Yangtze River Delta’s strategic location and industrial chain resources to become a key supplier in global stainless steel sector. CrAl6 FeCrAl Alloy Foil is one of our main products and has gained the trust of customers with its high-quality products.

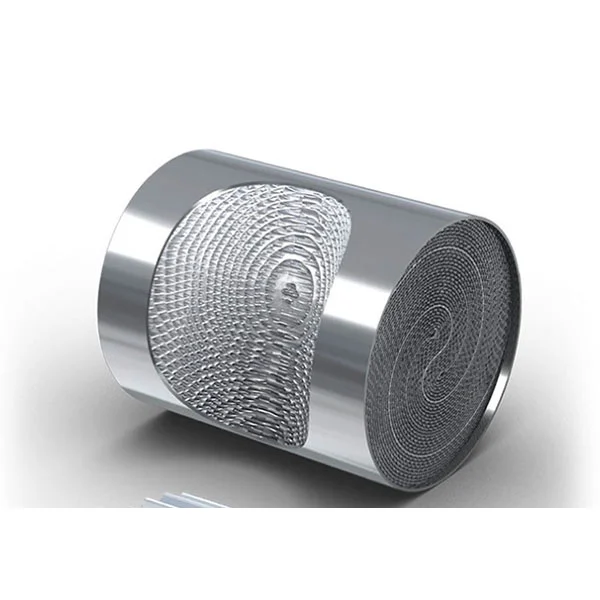

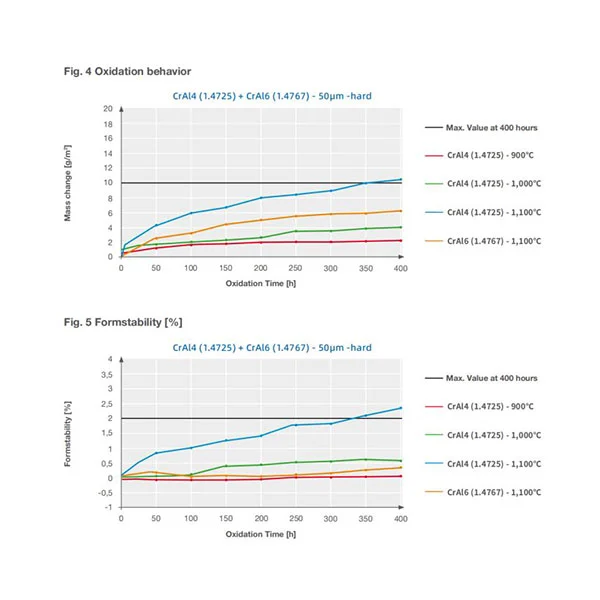

CrAl6 FeCrAl alloy Foil is a high-performance iron-chromium-aluminum alloy material, featuring excellent oxidation resistance, high-temperature performance and good mechanical properties. It’s mainly composed of iron (Fe), chromium (Cr) and aluminum (Al), and usually contains trace amounts of rare earth metals (such as rare earths) to further enhance its high-temperature stability and corrosion resistance.

| GRADE | Chemical Composition | ||||||||

| Cr | AI | Cr | AI | S | P | Mn | Ni | N | |

| 0Cr21AI6 | 19.0-22.0 | 5.0-7.0 | 19.8946 | 5.4475 | 0.001 | 0.014 | 0.097 | 0.1099 | 0.0057 |

CrAl6 FeCrAl alloy Foil even when exposed to extremely hot environments, this film demonstrates excellent mechanical strength, making it suitable for long-term use in high-temperature applications. Its unique alloy composition forms a dense layer of aluminium oxide on the surface when heated, serving as a protective barrier to prevent further oxidation and corrosion, and significantly extending the lifespan of components made of this material.

CrAl6 FeCrAl alloy Foil is super resistant to corrosion—it doesn’t rust or break down easily, even when exposed to nasty stuff like sulfur and carbon. That’s why it’s a top pick in tough industries like chemicals and energy. It can handle high heat without weakening, making it perfect for extreme conditions.So where do we actually use this stuff? Well, one big use is in industrial furnaces—it’s great for making heating elements because it can take the heat nonstop without failing. Cars also benefit from it, especially in exhaust systems, where it fights off corrosion from fumes and handles wild temperature swings like a champ. Aerospace engineers love it too. They use CrAl6 FeCrAl alloy Foil in things like heat shields and insulation because it’s both lightweight and tough as nails.

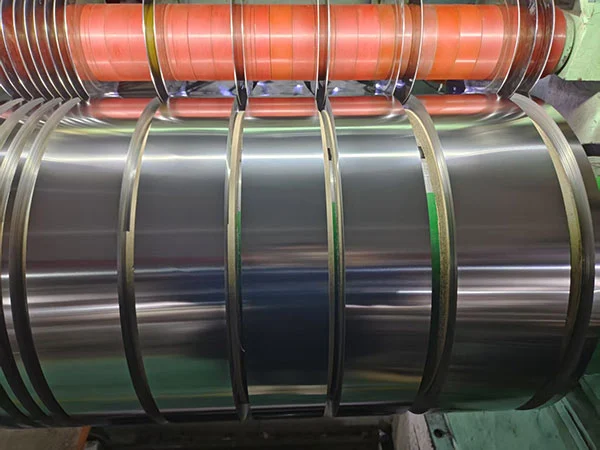

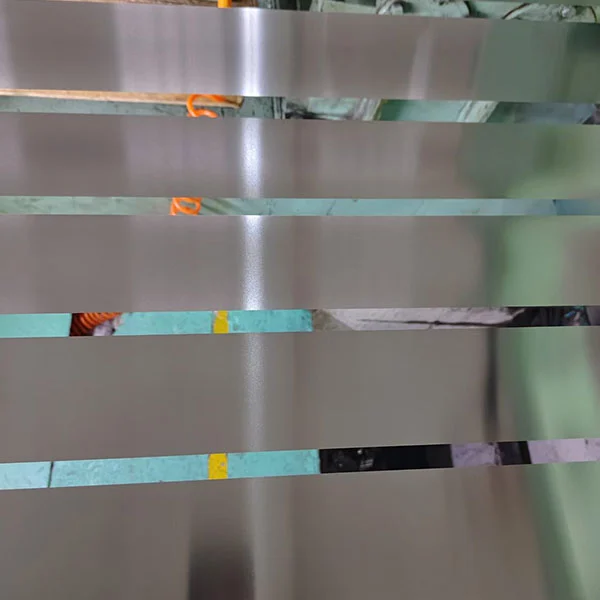

CrAl6 FeCrAl alloy Foil is made up of 15-20% chromium (Cr) and about 6% aluminum (Al) mixed into an iron (Fe) base. To boost its performance, we also add a small amount of yttrium (Y) or other rare earth elements. The whole process involves vacuum melting, then hot and cold rolling to get it down to a super-thin 0.01-0.2mm thickness. After that, we do hydrogen annealing to relieve any stress. Thanks to its awesome heat and corrosion resistance, CrAl6 FeCrAl alloy Foil is perfect for heating elements and even nuclear uses.

Our dedicated loading team ensures meticulous handling of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods (CrAl6 FeCrAl Alloy Foil)arrive in safe condition.