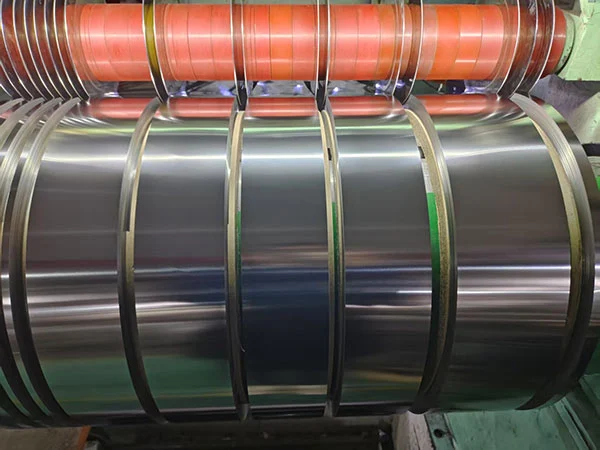

Ningbo Huali Steel Co., Ltd. is a leading manufacturers of 0cr21al6 FeCrAl alloy coil (DIN 1.4767 FeCrAl Alloy Foil), 0Cr18Al4 (DIN1.4725), etc. We have more than 17years experience in producing 1.4767/Cral6/0Cr21Al6 FeCrAl alloy coil, 1.4725/Cral4/0Cr18Al4, 0Cr15Al5, etc. It can be used in various kinds of middle-high end applications with our ultra thin thickness.

DIN 1.4767 FeCrAl Alloy Foil is a special alloy with iron, chromium and aluminum as the main chemical elements. High chromium content provides corrosion resistance, aluminum elements form a dense oxide film, giving high temperature oxidation resistance; low carbon control ensures processability and ductility. 0Cr21Al6 FeCrAl alloy coil has become an ideal choice for industrial and civilian high-temperature components due to its high cost-effectiveness and excellent electrothermal performance.

| GRADE | Chemical Composition | |||||

| Cr | AI | Ni | Si | Fe | P | |

| 0Cr21AI6 | 19.0-22.0 | 5.0-7.0 | <0.6 | <1 | Moderate Amount | Moderate Amount |

Common forms:

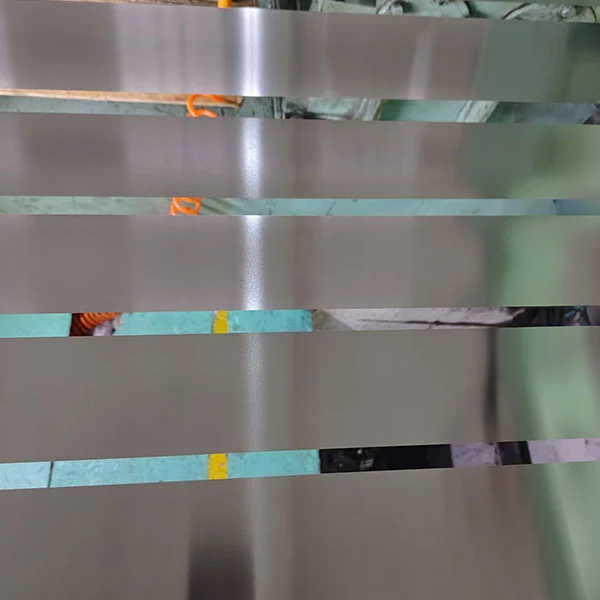

Thin strip: thickness 0.01-0.3mm (such as 0.05mm ultra-thin strip), strip processing for electric heaters and three-way catalysts.

Implementation standard: China national standard GB/T 1234-20123.

Heat treatment process: annealing temperature 950-1050℃, eliminate stress and improve toughness.

Core performance advantages:

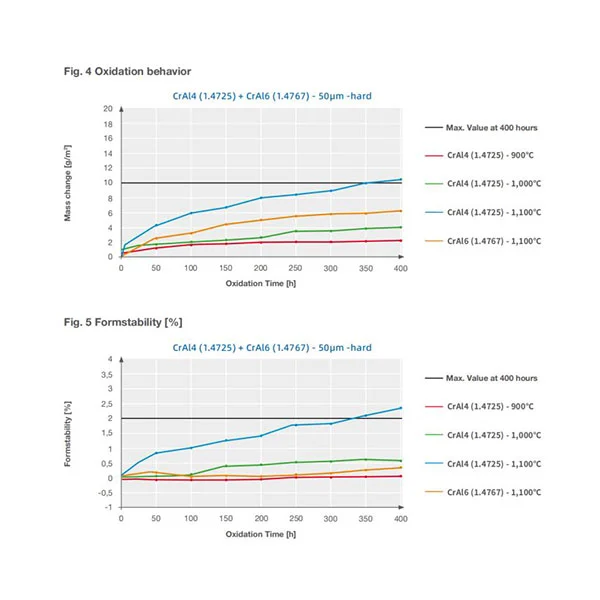

Oxidation resistance: A dense Al₂O₃ film is formed on the surface at high temperature, which can resist continuous oxidation at 1250℃, and the service life is 2-4 times that of nickel-chromium alloy.

Corrosion resistance: Resistant to sulfur and sulfide corrosion, suitable for sulfur-containing industrial atmospheres (such as heat treatment furnaces).

High resistivity: Achieve efficient electrical energy-thermal energy conversion, allowing the design of larger wire diameter components and extending service life.

High surface load: Fast heating and material saving, suitable for compact electric heating devices.

Does not contain scarce nickel elements, and the cost is about 30% lower than that of nickel-chromium alloy

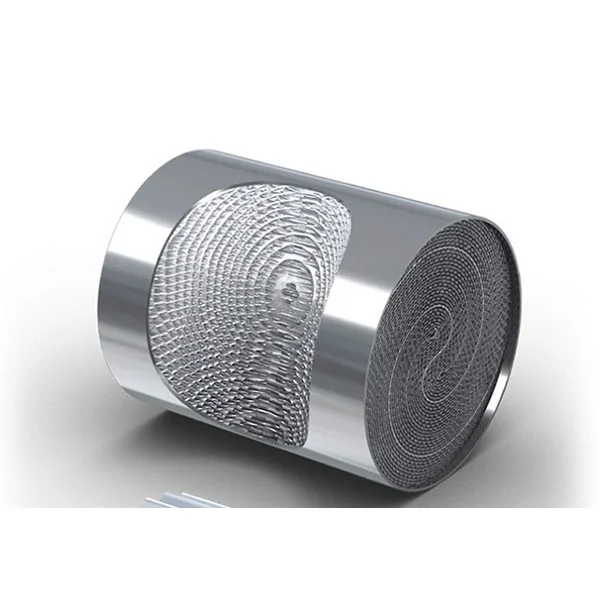

0Cr21Al6 FeCrAl alloy coil applications:

Industrial electric heating equipment (electric furnace wire, heat treatment furnace resistance belt)

Household appliances (electric kettle, oven heating tube, electric heater)

Aerospace (engine high temperature sensor components)

Emerging fields (three-way catalytic converter carrier, electric heating film)

0cr21al6 FeCrAl alloy coil vacuum induction melting or electric arc furnace dual process is used to ensure the uniformity of composition and control the burning of aluminum elements. After smelting, ingot homogenization annealing treatment (1150℃×8 hours) is required to eliminate segregation and optimize the organizational structure.